The long lost interview with David Karlin

by Urs König

Document informationInitial document name: The long lost interview with David Karlin.doc(x) Current document name: The_long_lost_interview_with_David_Karlin.docx Type: Interview Interviewed person: David Karlin Interviewer: Urs König Topic: David Karlin’s work at Sinclair Research Ltd. in general and the QL in particular. Date of interview: Friday January 25th 2002 & Friday February 8th 2013, yes 11 years in between. Location of interview: In David’s car and in his home in London, England; on the slopes of Gstaad in the Swiss Alps. First published in September 2013 in the QL Today magazine Volume 17 Issue 4 (The Final Issue). Re-released on January 12th 2014 as part of the “QL is 30[1]” activities. © 2002-2014 Urs König |

Structure

The long lost interview with David Karlin

Before I start

This article was lying around as handwritten notes and document snippets for more than a decade until the upcoming demise of QL Today meant “now or never”. By pure coincidence another event - of which you will read further down - made it easier for me to complete it. As a kind of farewell present to the loyal readers I have invested some time to write it down in a proper form, get it reviewed and completed with the help of the interviewed person and the editor of the QL Today magazine. Enjoy reading!

Get personal

After my QL development, publishing and trading activities faded out in 1992 and came to an ultimate halt in 1995 I became a silent follower of the scene and my interests in the QL shifted to two major topics 1) people and 2) preservation.

Over the years I have learnt that the QL changed my life in many aspects. Summarized I can say that it changed it in very positive way. I would say that without the QL and its technology I would not have made the career the same way as I finally did.

Rewind

It must have been one day in late 2001 when the virus of investigating the QL’s history infected me. About the same time I decided to produce the QL/E distribution CD-ROM with all the QL emulators and a large public domain library and launch it as a kind of birthday present at the QL’s 18th launch anniversary on January 12th 2002. My mailshot of that day also reached David Karlin.

Just a few days after I had made the first contact with him I had to attend a conference in London. I took this opportunity to meet David in person. Some more emails back and forth and we agreed to meet after work on Friday January 25th 2002 at Highgate station in northern London. I arrived by tube at about 6 p.m. and stepped out into a dark and rainy evening. David was already waiting for me in his golden Lexus in the car park.

Small world

After a short welcome David first wanted to know how I found his email address. To cut a long story short, I was investigating the QL’s history for the mailshot at the 18th launch anniversary. I had tried Google-Search which did not show much of relevance. I then emailed a few email addresses I had collected and the best response came from Paul Bass of BSS Audio who wrote me that 1) Yes, he did know the David Karlin I was looking for and 2) David had been MD at BSS Audio, but had left them and was now head of R&D at Sage Computing. Unfortunately he was unable to give me his contact details at Sage. Some weeks later I stumbled across (using Google-Groups) a newsgroup message[2] of Rupert Goodwins (another former Sinclair employee) where he wrote:

“Sage.com? Where David Karlin, one of the QL designers, has just gone to be head tech bod?

Small world... (it is, I lost it under my bed the other night)”

I then made some simple logic and added David’s name the same way to @sage.com as seen in one of the email addresses in that newsgroup message thread. Gotcha!

What followed was a discussion on Google and how amazing this website is. David used Google as his default page/portal at that time. We were also asking ourselves of how they make any money. Our thinking then was that they could make a fortune if they linked their search results with ads or sold the search result ranking. Nowadays we all know what big business selling ads alongside search results has become. Time was flying and we arrived at David’s home where his wife Alison and their children Lisa and Sam were already waiting for us.

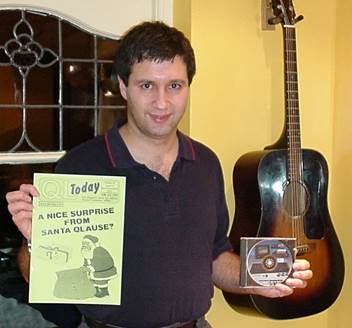

A nice guy

We had a beer and a chat on god and the world. David likes music, be it acoustic or electronic. There was a guitar hanging on a wall and David proudly expressed the benefits of his DSP controlled sound system. We talked about the QL as well and how it compares or better differs from audio electronic designs (in terms of electronic noise and signal quality). Then it was time for dinner where Alison served a tasty sole fish with potatoes followed by a dessert made of yoghurt and fresh fruits. We talked about family, work and the city. As a former stock trader Alison had a lot to tell in this respect. After the meal she took the children to bed and David and I continued to talk about the QL until at about 11 p.m. when it was time to leave so as not to miss the last tube. David was kind enough to drive me back to the station and I took the tube to return to my hotel. It was a pleasant and enriching evening which I will never forget.

David in his home in London in January 2002 holding the QL Today magazine Nov/Dec 2001 (Volume 6, Issue 4) and the QL/E CD-ROM (QL software distribution). Ref: MVC1386F

A decade later

Over the next decade we stayed in contact in loose form. An email a year, Christmas greetings, a word about how fast our children grow or how the ICT industry is changing or the like was more or less all about it. Around the QL’s 25th anniversary in 2009 communication increased a bit but then came down to the usual level. While checking the web for QL history updates in early January 2013, I had learned that David visited the “Sommets Musicaux De Gstaad” festival in 2012 and after an email back and forth it was clear that he would also attend in 2013. David had a lot to do at and around the festival. I was about to leave for a one week skiing vacation with my family in Les Gets in the French Alps. Even our schedules were tight we agreed to meet on Friday February 8th 2013 in Gstaad for a joint ride on the slopes in the Swiss Alps. As the weather forecast was not that good for Friday - the week already brought a lot of snow - I left home very early at 6:30 a.m. What normally is a 2 hour journey became a 3 hour drive at difficult road conditions. I arrived some 25 minutes late at the hotel and met David in the Lobby just at the moment when he stepped up from the basement with his skis. His wife Alison joined us a few minutes later. Ready to go! Instead of using the free shuttle bus I used my car, but instead of taking the direct route to the desired lower terminus we went an alternative way suggested by the receptionist. This took us around the valley on deep snow covered private roads. We then decided to return to known paths and finally ended up where we wanted to start our skiing. The day started funny. Alison left us to take a 2 hours private ski lesson. We appointed to meet her for lunch at the Snoasis Restaurant on top of Eggli.

A great skiing buddy

David and I went directly up the hill and started what became 2 hours of great skiing on Eggli, Chalberhöni and La Videmanette. The sun played hide and seek with clouds. There were almost no other skiers around and the snow was just awesome. David even tried to ride the deep powder. Skiing may not be the first type of sport you assign to Englishmen, but David is definitely a good skier. While going uphill with ski and chair lifts or even cable cars we had great chats on our lives, family, education, work, IT industry, music, movies (mainly James Bond), the world and guess what?, the QL. On the IT topic, where 10 years ago we talked intensely on Google, this time it was about Rich Internet Applications (RIA) where we discussed our experiences - David developed and maintains the CMS for his businesses in PHP, CSS and HTML5 with all sort of technologies - ending up in HTML5 versus Native Apps and how Apple changed the world. At noon we met Alison and her private ski instructor Gilbert in the Snoasis restaurant. We enjoyed glühwein, beer, hot chocolate and sausages for lunch and had great conversations in different languages - English, French, German and even Portuguese. David speaks fluent French as he lived a few years in his childhood in Paris. He also speaks Portuguese as he lived a year in Cascais near Lisbon at the Atlantic coast in Portugal. Time was running fast. David and Alison needed to return to the hotel to freshen up and change for the afternoon concert of the festival. Outside the restaurant Alison was so kind and shot a great picture of David and me. A last downhill run then a direct drive back to the hotel, farewell and goodbye. On my way back home, driving was easy as the sun brightened up the afternoon. It was a real pleasure meeting David and Alison again after some many years. We also had great skiing, I really enjoyed it. And talking with them is always a pleasure and enriching.

Urs and David in February 2013 on the slopes of Gstaad in the Swiss Alps. Ref: IMG_2053

Questionnaire

You may say yourself, nice story but what about the QL? Well, David was so kind to answer specific questions about Sinclair and the QL.

Before Sinclair

Q: Please tell me a bit about your education and employments before Sinclair.

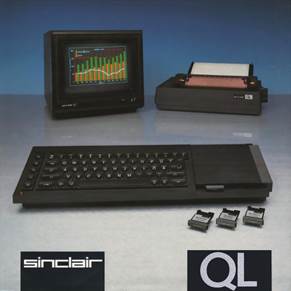

DK: After studying Engineering and Electrical Sciences at Trinity College, Cambridge, I was hired by Fairchild. First 1 year in the Far East at their production plant, then for 1 ½ years at their R&D site in Palo Alto, CA. While working there I was impressed by the workstations we had. They offered multitasking, windowing, etc. All you could dream about in those times. But those machines were expensive like hell. I thought for myself “I can do this (core unit, CRT, printer) for less than £1000”.

Employment at Sinclair

Q: Why/How got you employed by Sinclair?

DK: While working at Fairchild in the US I got married for the first time and as my wife did not like the US I was looking for a job back home in England. I went to see Geoffrey King, a head hunter in Cambridge, about a completely different job, and Geoffrey told me about the job at Sinclair – I was later told that it had been advertised as looking for “the greatest computer designer in the world”, although I never actually saw the ad. I met Clive for an interview, we both felt a perfect fit and he offered me my American salary, which was about 30% higher than the going rate in the UK. I immediately decided to take the job.

Q: For which main task(s) were you hired by Sinclair?

DK: To build Sinclair’s next computer code-named ZX-83 which eventually became the QL.

Q: From/To which date did you work at Sinclair?

DK: I joined Sinclair in summer 82 (must have been August IIRC) and stayed until the sell-off to Amstrad in April 1986.

Q: What projects have you been involved in, in which order?

DK: It was all about the QL. After the QL was done and teething problems solved, I got bored a bit. Nigel Searle felt that and said to me one time “I don’t want to lose you David”. I said “The next thing I want to do in my career is to start my own business, so can you give me a commercial role”. So I became production manager in one of the 1985 reorganisations. I took over the job from David Chatten, though I believe Dave was still working for Clive, presumably in the C5 arena. In this critical and difficult time at Sinclair we did economics in practice under a difficult cash situation but were able to pay back debts of about £8m until Clive sold the thing off to Amstrad. All but a very few employees were fired then, so it was time for me to move on.

Q: What is your today’s relation to the people you had been working with at Sinclair or collaborating partners?

DK: I’ve met John Mathieson and Richard Miller a few times. I’ve lost contact with Tony Tebby and many others. I don't see Clive any more. Sadly Ben Cheese who became a close friend died of cancer back in 2001 at the age of 46. Philip Hart, who was manufacturing director at our sub-contractor THORN EMI Datatech became a close friend.

Q: What good/bad/funny memories you have from your time at Sinclair?

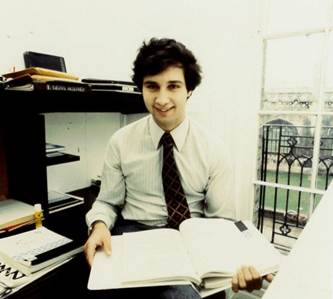

DK: My first hour in the office was fairly unforgettable. I showed up at the tiny office in King's Parade, and no-one had a clue who I was or why I was there. So Stuart Honeyball, one of the engineers, said to me “Ah, you've come to help us, have you?” and set me to work opening packets of resistors from Radiospares and putting them into drawers. I clearly remember thinking “Oh, well, if they want to pay me 27 grand a year for cutting up RS packets, who am I to complain”? An hour or so later, Mollie Pearson, Clive's PA, arrived: she *did* know who I was and the job started in earnest. A textbook example of how not to welcome a new employee!

David in his office at Sinclair Research Ltd. in Cambridge in 1983. Ref: Who's who at Sinclair 1983

About the QL

Q: Even though there are already several books and articles written by insiders, outsiders or even journalists describing the QL’s history and development it never became crystal clear how the project was started, organised and who did have which role/leadership to what extent? Who was the overall project manager? Who was in charge for what sub-projects (electronics, software, production, marketing, etc.)?

DK: There wasn't a single project manager in the conventional sense. I “did” the hardware and pretty much managed myself, Tony Tebby “did” the software similarly, Rick Dickinson the industrial design. Jim Westwood was in charge of the engineering lab, so I suppose that theoretically, Tony, Rick and I all reported to Jim; in practice, decisions were taken at meetings chaired by Clive. David Southward contributed the Microdrives. When things went into production, Dave Chatten became in charge of that whole process, assisted by a new project manager called John Munford. John was a pure manufacturing bloke. Another important manufacturing guy for the QL was Chris Cowsley. Nigel Searle was MD of the company and therefore attended many of the meetings and contributed a fair bit to the decision making - and I'm sure made most of the key commercial decisions, with which I wouldn't have been involved at the time - I blush to think of what an ivory tower I lived in.

Q: What tasks (even details) did you do on the QL?

DK: I mainly worked on the electronics, the semi-custom ICs ZX8301 and ZX8302 and the printed circuit board (PCB). I also worked closely with the chip and PCB manufacturers and the production plants. I’m pretty sure that I didn’t do any software/firmware. Unlike earlier Sinclair computers I decided to do the custom chips in CMOS VLSI and not in bipolar LSI which I considered already as a dead end technology at the time. Only Ferranti and Fairchild did still push their bipolar designs, the industry trend was already towards CMOS.

Q: What’s the most accurate name or description for those chips?

DK: ASIC is the correct generic term: ULA is specifically Ferranti's word for a gate array, a form of ASIC where all the layers except the metal and interconnect are fixed. If I remember rightly, the ZX8301 was a gate array (but I'm not 100% sure anymore), and the ZX8302 was definitely not, which is why it was so painful when there were Microdrive problems – a gate array could be turned round in about a month, while a semi-custom chip like the ZX8302 need six months and some seriously expensive mask changes.

Q: Who else did work on the QL electronics/hardware/production?

DK: Rick Dickinson[3] did the industrial design (case, keyboard) in all aspects (drawings, models, prototypes, injection moulding specifications). The important one for me was Ben Cheese. I'm struggling to remember what the others did on the QL, as opposed to the Spectrum work, which is what John Mathieson and Martin Brennan were mainly engaged in. I'm sure there were lots, but my memory's failing me. I remember Aaron Turner, who was very young when he joined us (even compared to the rest of us!), but I can't actually remember what he was working on.

Q: Was it clear at that time that it will be a professional computer, not a home/hobbyist machine?

DK: In retrospect, I don't think so. I heavily wanted it to be professional; to this day I'm not sure that Clive shared the same vision.

Q: How you personally judge the QL from today’s perspective?

DK: Technically it was an excellent product, at least the digital part, not the Microdrives. Compared to the ZX Spectrum which for example had a memory refresh which was out of the specifications. Compare the QL’s PCB with the one of the Macintosh and you’ll see the higher integration we have reached using the custom chips. In recent years I've often thought about “what could have been”. You know, the direction of the QL was right (the Macintosh proved that). OK, we had those early teething and supply problems but some of the main reasons we failed in the long run were:

1) I don't think Clive really wanted to have a professional computer, more a kind of a more powerful ZX Spectrum. Tony Tebby and I shared the same vision of a real professional computer, a real personal computer. The problem was that we never really resolved this with Clive, so the product ended up falling between two stools.

2) Clive wanted to make the Microdrives work, but we would have done better to go for floppy disk drives the way Amstrad did. Alan Sugar knew that FDD prices were around £60. He went to Panasonic who had those 3” FDD ready for the market, but were not in a good market position. He said them “You want to enter into the FDD market the big scale? I’ll pay you £20 per unit and you’re in!”. He came back with a deal and his CPC and other machines got working disk drives for astonishingly low cost. Clive decided that we had to go the hard way. We had to invest a tremendous amount of effort, time and money to get the Microdrives working properly. Integrating two analogue devices constructed out of a tape loop, a tape head, a drive motor and an ULA into an apparatus like the QL which is full of noise/RF is a real challenge. Ultimately, we never really made them reliable enough and this turned into the QL's Achilles’ heel. External Microdrives as used with the ZX Spectrum are a much easier task.

With real FDDs instead of Microdrives and other changes from the Sinclair way of doing it I could have built a professional machine to compete the Macintosh for 1/3 of the price.

QL fact & figures

The QL had its early teething and supply problems. First machines - with the infamous dongle kludge - were shipped starting at the end of April 1984. There was a call to send those machines back for ROM fitting and other mandatory modifications[5] in summer 1984. At about the same time the order backlog was cleared and volume production started. UK Retail sales started in autumn 1984 as originally planned. At the same time a Sinclair QL branded CRT colour monitor called Vision and the first Sinclair badged Software titles (Chess, Assembler, Toolkit, Cash Trader) became available. But US and European export sales got a massive delay. Selected European markets got at least delivered with the UK edition (English keyboard layout, English software and user guides) in late 1984. The

QL saw a kind of a relaunch in February 1985 with the introduction of version

2 of the PSION business software[6],

the Technical Guide[7],

many more software titles and 3rd party peripherals. Timed with the 1985 London PCW show the recommended retail price of the QL was reduced from £399 to £199.95 ($499 to $299 in the US, DM1998 to DM1298 in Germany) and two more Sinclair badged peripherals were launched, the Seikosha made QL Printer and the Micro Peripherals made QL Floppy Disk system. No new Sinclair badged QL products were introduced after the autumn 1985 sales offensive. UK production of the QL was halted in 1985 because output had exceeded demand. Korea (Samsung) production of the QL - at least the German edition - continued until May 1986, just weeks after Amstrad bought the Sinclair computer business and brand name on computers and axed the QL. A research done based on the serial numbers of many hundred QLs[8] indicates the following production figures:

Altogether it appears that about 140,000 QLs were made. |

Design aspects/flaws

Q: Why the IPC chip was added to the design? In other words: Why the ZX8302 was not covering keyboard/controller ports, sound and RS232 receive on its own? If there was a need to add an additional large chip (microcontroller) like the I8049, why not choose a more advanced chip in the same price range (or below) which could even produce proper sound (e.g. AY-3-8910 as known from many other micros, which later in 1985 was being used by Sinclair in the ZX Spectrum 128K)?

DK: We did not succeed to pack all the planned features into one 40 pin chip. I remember for sure that if we had to go for a 48 or more pin package instead of the 40pin we were using it would have cost a tremendous amount more. That would have doubled the cost of the chip, made the PCB more complex, maybe even bigger and more costly. Not sure if the board would still fit into the already designed case. The I8049 was a cheap standard microcontroller and was used as a cost driven compromise. We implemented the needed functionality by on-chip firmware to make it work, at least sort of.

Q: Another issue is why the two RS232 ports did not support separate baud rates? Without this feature the ports could almost never be used to have a printer on one port and a modem on the other working at the same time.

DK: Because in fact, there was only one RS232 receiver, which we tried to multiplex using the RTS and CTS signals – one cost cut too far, which, in retrospect, has to rate as one of the more embarrassing design decisions I've ever made.

Q: The QL’s Microdrives use the same ULA as the ZX Spectrum’s Microdrives. The way the Microdrives are handled by the QL’s ZX8302 chip and by the firmware is different from how it is handled by the ZX Spectrum Interface 1 which was completed and launched several months before the QL in summer 1983. What is the story behind that? What about speed vs capacity vs reliability, etc.?

DK: We couldn't have afforded separate ASICs for the Microdrive logic and everything else the ZX8302 had to do. So it was clear that we were going to use a single ASIC to cover everything. The critical failure was this: there wasn't a way of doing an analogue PLL in the CMOS technology we chose for the ZX8302, so I designed a digital PLL, but a miscommunication between me and Ben Cheese – one of those classic “conversations in corridors” that went unchecked – resulted in me making a wrong assumption about the accuracy of the duty cycle produced by the Ferranti ULA. The Spectrum Microdrives were adequately reliable, if not fantastic, but the inadequacy of the digital PLL was very difficult to fix.

Q: What is the problem with the network hardware/timing/protocol? Were the network ports just a more developed cassette interface with a higher frequency?

DK: Actually, I can't remember it being all that bad – it pales into insignificance in my memory compared with the Microdrive troubles. But it was indeed a single “bit-banging” interface – another of those “we can’t add any more logic gates or it will get too expensive” decisions.

Q: What was the original plan for the ZX8301 and how it evolved, got changed?

DK: The ZX8301 is the part of the QL I’m the most proud of. We succeeded to pack all planned functionality into this chip.

Q: Why has a non-common FLASH option been implemented and not a more desirable and usable 16 colour option (BRIGHT of the 8 base colours or real 16 colours)? Was this because of Teletext/BBS/Videotex/MicroNet/Prestel or the like had flashing characters?

DK: I hardly remember this. The ZX8301 is purely digital, so to get multiple colour levels, we would have needed an extra output which would have fed a primitive DAC. This would have needed another pin, and we didn't have one.

Q: Reason for adding a TV modulator to a professional machine? Reason the TV output signal was significantly poorer than of most other micros using the same kind of TV modulator. Even late builds of the QL (including Samsung built QLs) produce a very poor quality and blurry TV picture. Remember that the modulator was located close to the Microdrives and power regulation electronics.

DK: The TV modulator came in quite late in the design, maybe two to three months before the launch. It was indeed not following our original plan to produce a professional computer.

Q: Reason for the MC68008 and not the full blown MC68000 CPU (a typical micro of that era runs about 2 to 3 times faster with this chip)? Some said that the chip price was not a big difference if bought in high volumes. Was there an idea of building a cheaper machine because the CPU is 8-bit on the external?

DK: The 68000 was far more expensive than the 68008 at that time (1982/1983). Cost was very important at Sinclair. Saving ½ £ here and there was key.

Q: Why the QL ran at 7.5Mhz (15Mhz quartz) clock rate even though all used standard chips were able to run a 8Mhz? The QL could have 7% more speed at no additional cost. Was there a design decision (Sinclair’s flat-screen tube) or timing problem in the ZX8301 at one time during development which made it necessary to lower the system clock to 7.5Mhz?

DK: The design was to work with a CRT monitor not a TV. The DRAM timing was difficult so we used the scanline to the very max. Because you have to match the clock on your CPU to the minimum cycle time of the DRAMs. I can't remember the specifics, but if you get two clock cycles per DRAM access at 8Mhz, you have 250ns in which to cycle your DRAM. If the DRAM won't cycle in that time, you have to add wait states, which is even slower than making the clock faster.

Firmware

Q: What’s the real story about the operating system? What was the original plan? Who decided which changes to this plan, when and why?

DK: IIRC, it was decided to run both projects (the in-house and the GST one) in parallel and use whichever came out better. But I really can't remember when that was decided. I assume that Clive and co got frightened about whether Tony and my work was going to deliver, but I don't remember being told this.

Q: What about the initial 32Kbyte ROM design which ended up in 48Kbyte? What was planned to be in the ROM initially (e.g. only the OS, the OS and BASIC, the OS and a cut down BASIC as a kind of Shell/Command Line Interface)? What was planned to be loaded from Microdrive cartridge (e.g. the BASIC)?

DK: I don't think there's any doubt on this one: the ROM was supposed to have OS and BASIC, all apps were supposed to load from the Microdrive.

Q: Who leaded the firmware for the MC68008 (OS, BASIC) and the I8049 (IPC) issues, who (else) was involved in firmware design and writing?

DK: My colleague Tony Tebby did most of the firmware, the operating system. Jan Jones – who was recruited by him – assisted him and wrote the BASIC interpreter.

Manufacturers, production plants, facts and figures

Q: Who manufactured the QL for Sinclair?

DK: THORN EMI Datatech manufactured QLs for us. IIRC we had a dedicated production line at their Feltham plant. I was there quite a few times to discuss details and help them to ramp up production, testing and quality control programmes. They used ROM port dongles as known from early shipped QLs, but those dongles contained various system test software. The production plant in Feltham was managed by Philip Hart.

Samsung became our second source. As UK production was higher than demand we started with them to produce QLs for foreign markets, starting with the US edition and following with the German edition. Samsung made QLs were the better ones, they had much reduced noise as they needed to suite US and German RF regulations. It took us quite a big effort to make the QL US FCC compliant, especially as the product was not designed around such principles and rules. Do you know who knows best such issues? Guess… Yes, professional audio electronic systems as in such systems noise has to be avoided 100%. Based on my experience gained at BSS Audio I could design a noiseless QL nowadays. The PCB layout and lines would look completely different. I visited Samsung in Korea a few times but never saw their production line. IIRC we did not own a dedicated production line for the QL, we got slots to produce batches. You know Samsung was already a giant company back then. Even the hotel which we stayed in was owned by Samsung. Almost “everything” around us in Korea was Samsung. But they were not yet that big in consumer electronics. The ZX Spectrum+ and QL manufacturing was something new for them. It was one of their first sub-contracting jobs. IIRC Dave Chatten found them to do the job for us. Working together was not that complicated. Yes, time was shifted by many hours (UTC+09:00) and language was an issue. No one at Sinclair could speak or understand any Korean, but their English (at least understanding) was good enough to make it work. Remember that at those days we had no email, not even fax yet. Communication was mainly by Telex. We hired a guy (John Munford) at Sinclair who was in charge for the coordination with Samsung. He flew to Korea quite often.

Q: How comes that the QL went through about 18 build-standards and 15 PCB issues during its relatively short production lifespan?

DK: Concerning the high number of build standards, modifications and PCB issues. You know we had those early teething problems which forced us to implement changes. We were under huge pressure because the product was already launched, marketed and sold to customers. Lead time was becoming a problem. A new improved PCB design took about 2 to 3 weeks if not more to get produced and make an impact. Nowadays you have lead times of 1 to 2 days. As there were more and more improvements many were implemented as modifications.

You know production engineering and quality control was a disaster at Sinclair. The reality was somewhere between "severe problem" and "total nightmare". Even some guys like David Chatten were real professionals in pushing sub-contractors and getting cheap prices, Clive’s understanding was still the way he experienced in the 60s when he bought factory rejected transistors, measured them, combined those who were working together and built a product out of them, saving some pennies.

I on the other hand came from Fairchild were we already went through a process of improving manufacturing engineering. Of the RAM chips we were producing only about 35% were usable, our Japanese competitors had an output of 80% usable ones. So they could sell for half the price and still making more profit than us. They became a real threat to us and we had to improve our production quality dramatically. I came with this experience to Sinclair.

Q: Were all UK made QLs made by THORN EMI? What about other companies (Timex in Dundee, Scotland or AB Electronics in Abercynon, Wales) who manufactured products (ZX Spectrums, Spectrum+, ZX Interface 2) for Sinclair? Did they build any QLs or were there at least talks with them to build QLs?

DK: I’m sure AB Electronics did something for us. I’m not sure it was QL related, maybe it was ZX Spectrum related.

QL+

Q: What do you recall of the QL+/Tyche developments? What were the technical specifications for the upgraded QL? How far did the development evolve until the machine stopped?

DK: It was a repacked QL design with additional RAM, minus Microdrives, plus two 3 ½” Floppy Disk Drives and a CRT monitor. We did not have the case ready so it was never a real machine.

After Sinclair

Q: How did your career evolve after Sinclair and how did Sinclair and the QL make an impact to your professional life?

DK: After leaving Sinclair in April 1986 I together with Mike Leadbetter, a colleague who also worked for Sinclair, founded a company called Alfa Systems where we developed and marketed a PC network card using only 3 chips making it possible to offer them at a very competitive price. We sold them among others to Sage which I knew from the time at Sinclair where they produced an accounting package which we sold under Sinclair’s Silver Label. Alfa went on to market a product called the Diskfax (remember a world in which email attachments didn't really work, and you'll get the idea). From the time working with THORN EMI Datatech on the QL I knew Philip Hart who later also went on and offered me a job in the audio electronics industry, so I became MD at BSS Audio in 1994. At BSS we did 90% export and made about £4Mio revenue per year. When it was again time to move on I got the job at Sage. The two founders of Sage still remembered the QL and my work at Sinclair so the QL helped me to get all new jobs so far.

David, thank you very much for your time, patience and support.

QL forever!

Lucerne, June 13th 2013

Urs König

About the people

|

O o O o O